Hiltner 2.4m Rotator Guide

The instrument rotator is essential if you desire to account for parallactic angle (p-angle) or if you intend to perform multi-object spectroscopy (MOS) with OSMOS. The rotator can be operated via a hand paddle found in the dome or from the GUI found on the mdm24ws1 workstation. Movement resolution is as good as 0.01º when controlling from the GUI.

Safety Rules for Operation:

• It is imperative that the mirror covers be open prior to using the rotator. Failure to do so could cause the center baffle to rub against the covers, resulting in paint chips (or worse!) falling onto the primary mirror surface.

• It is a good idea, especially for motions larger than 1º, to bring the telescope up towards zenith prior to rotating. The friction drive-system can lose counts if there is too extreme of a gravity vector when operating.

• For any motions greater than 1º, cables should be carefully monitored during movement. There are various areas where cabling can get caught on equipment, depending on telescope orientation.

Operation From Within the Dome:

A hand paddle is located to the north of the telescope, next to the dome shutter controls. The paddle has two buttons that are labeled for clockwise (CW) and counterclockwise (CCW) rotation. These directions are with respect to an observer looking up at the mirror cell from below. There are limit switches that confine rotation to between roughly -85º and +96º. While these correspond roughly to safety limits for cabling, it is still imperative that the observer watch during any large movements from the dome floor. The rotator angle is displayed on the TCS monitor which is also displayed on a remote monitor from within the dome.

Rotator Hand Paddle

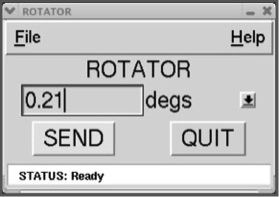

Rotator GUI

Rotator Electronics Box

Operation From Within the Control Room:

The rotator may also be operated via the Rotator GUI on mdm24ws1. Control is based on relative offsets with a limit of ±4º per motion. Larger offsets should be initiated from within the dome so that cabling can be monitored. The GUI accepts offsets in degrees, arc-minutes and arc-seconds. Default is degrees. Enter the value of the offset in the input box and press the SEND button to initiate the offset.

Troubleshooting:

95% of rotator failures can be corrected by power-cycling the rotator electronics box on the telescope, which is located on the underside of the primary mirror cell, due East. An image of the box can be found above. To cycle, simply flip the switch on the left side of the southern face, count to 10, then flip it back on. You may also have to restart the GUI on mdm24ws1.

Sponsors:

The MDM rotator upgrade, performed in early 2011, was generously funded by the NSF grant to build the OSMOS instrument as well as by the Ohio State Department of Astronomy.